D&G Precision Mfg. prides itself in our flexibility in the parts we manufacture.

We have the capabilities to meet your needs. Have parts that need special fixturing? D&G has you covered there too. Utilizing our Gibbs cam software, D&G has built many dictated fixtures to meet our customers’ needs.

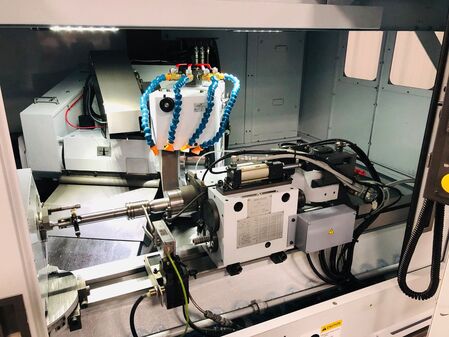

Turning parts from .125” in diameter and lengths as short as .060” & parts 16” diameter to 24” lengths. D&G’s milling department has capabilities to run parts from .125” x .125” x.125” to as large as 40” x 20” x 20” in size. Utilizing our 4th Axis capabilities with high pressure coolant system or live tooling in our state of the art twin spindle dual turret lathe.

RAMCO ULTRASONIC PARTS WASHER

*Parts cleaning is an additional service we offer!

LATHES

Vibratory Deburring

•Burr King Vibratory De-Burring Machine Vibra King 45

•Burr King Vibratory De-Burring Machine Vibra King 200 D&G also stocks many types/sizes of media for each application necessary |

Vertical & Horizontal MILLS

Metrology

Our Quality lab is well stocked with some of the best equipment, processes, and metrology methods in the business to ensure your parts are done right the first time, insulating our customers against non-conforming product & exceeding expectations at every opportunity

|

SAW CUTTING

Our climate controlled facility houses state-of-the-art inspection equipment that is kept in calibration traceable to NIST.

|

Grinders

•Mitsubishi RD23-B35A CNC Cylindrical Grinding Machine (6" Dia. x 16" Center Distance)

•Mitsubishi PD32 - B100A CNC Cylindrical Grinding Machine (11.8" Dia. x 39.4" Center Distance

•Okamoto ACC-16.24EX CNC Surface Grinder (16" x 24" table)

•Sunnen MBB1660K Honing Machine (4" Dia. x 12" Length)